Suction-blast machines are the most common blast cabinets in use, and Guyson’s Tech Support team regularly answers questions about how to get the maximum performance from suction-blast guns.

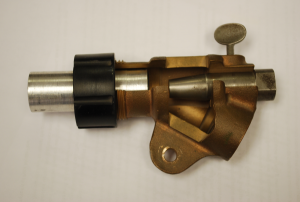

If you are not sure if you are working with a suction-blast gun, it is easy to recognize, because it has two hoses attached to it, one delivering compressed air and one vacuum hose drawing media into the gun. Pressure-blast nozzles have only one larger hose to deliver a mixture of media particles and air.

If you are not sure if you are working with a suction-blast gun, it is easy to recognize, because it has two hoses attached to it, one delivering compressed air and one vacuum hose drawing media into the gun. Pressure-blast nozzles have only one larger hose to deliver a mixture of media particles and air.

Whether you are newly responsible for a cabinet-blasting process and trying to understand how to make it more efficient, or you are a person who has done shot, bead or grit blasting for some time, you might find some useful tips in this article on fine-tuning suction blast media delivery.

This is an important topic because suction-blast systems are so prevalent, and because under-performing blast guns slow down the work and may result in finish variations that are unacceptable. The good news is that, ordinarily, you should not have to repeat the adjustment process frequently.

It’s OK, Go Ahead and Vent a Little

When compressed air is metered into a suction-blast gun through its air jet, venturi effects generate a powerful vacuum in the media delivery hose that draws media particles up to the gun, where they mix with the flow of air and are projected out through the nozzle. If the mixture of media and air is off, you will have either too much air and not enough media, or too much media and not enough air.

The air/media mix delivered to the blast gun by the media hose is regulated by what Guyson calls a pickup tube located at the bottom of media supply hopper, or occasionally the hopper at the bottom of blast cabinet. The pickup tube has vents that allow you to increase or decrease the amount of air in the mixture. More vent air reduces the number of media particles that are entrained in the flow of air to the gun, and less vent air increases the vacuum in the media hose and pulls more media particles.

The air/media mix delivered to the blast gun by the media hose is regulated by what Guyson calls a pickup tube located at the bottom of media supply hopper, or occasionally the hopper at the bottom of blast cabinet. The pickup tube has vents that allow you to increase or decrease the amount of air in the mixture. More vent air reduces the number of media particles that are entrained in the flow of air to the gun, and less vent air increases the vacuum in the media hose and pulls more media particles.

Your goal is to find the right balance of air and media, so the air flowing in the media hose is carrying just much media as it can. That way you will get the maximum number of media impacts per second to do the work as fast as your machine will do it.

It does not matter if you are working with a single-gun manual blast cabinet or a multiple-gun automated system, the diagnostics and the adjustments are the same, except Guyson Multi-Blast machine owners have to repeat the procedure for each blast gun.

Signs of Poor Media Flow

If you are trying to work with a suction-blast gun that is not throwing any media at all, the problem is usually a clog. It will probably be found in the body of the gun or the far end of the media hose, at the mouth of the pick-up tube.

With the compressed air supply off and locked-out, remove the nozzle from the blast gun, dump out the contents of the gun for inspection and use a flashlight to look in the gun body to see if you find some kind of debris blocking the flow of media into the blast gun – burrs, flash, big paint chips or foreign objects are the most common clog material. If the gun is clear, check for debris blocking the media intake of the pickup tube.

Adjustment Procedure

If you have media flow through the gun, but have intermittent surging (when the media hose fills right up and gradually empties out), or the gun just does not seem to throw enough bead or grit, you need to adjust the vent opening on your pickup tube to balance the mix and produce an even flow. Here is how Guyson service technicians make this adjustment.

Actuate the blast gun continuously at the blast pressure you normally use, and watch the flow in the media hose between the pickup tube and the back of the blast cabinet. Loosen the locking nut on the pickup tube adjustment screw. Turn the screw clockwise to decrease the vent air just to the point where the air stream becomes overloaded, the hose starts to fill up and surging of the media flow starts. Then, turn the adjustment screw counter-clockwise one-quarter turn at a time to increase the vent opening until surging stops.

Finally, actuate the blast gun on one or two more times, while watching the media hose, to check for smooth flow. Some users give the adjustment screw a last one-eight to one-quarter turn in a counter-clockwise direction before tightening the locknut.

Should you discover worn media delivery parts that need replacement, or if you have a question about optimizing the performance of your Guyson suction-blast system, please do not hesitate to call the factory toll-free owner hotline from anywhere in the U.S.A. or Canada at 1-800-633-6677 or use our on-line Contact Guyson form.