How does the Vaqua wet-blast system work and what can it do for me?

The Vaqua wet blast process is a unique blast finishing technique. The process utilizes a three part solution of shot or grit media, water and small amounts of compressed air to develop a scrubbing action on the surface being treated. It also may be referred to as slurry blasting or (somewhat mistakenly) vapor blasting.

The water portion of the process creates a buffer between the media particle and the work surface. The compressed air portion of the mixture regulates the degree of the buffering effect by varying the air pressure and volume of compressed air. The higher the pressure and volume of compressed air, the more aggressive the Vaqua wet blast process becomes.

The heart of the Vaqua wet blast process is our own design of solution pump, manufactured in the Guyson factory in Saratoga Springs, New York. The pump design is specific for wet blasting application, without bearings, seals, or packings. The interior parts of the pump, including the housings and impellor, are bonded with abrasion-resistant polyurethane rubber to give it a long and maintenance-free life.

The heart of the Vaqua wet blast process is our own design of solution pump, manufactured in the Guyson factory in Saratoga Springs, New York. The pump design is specific for wet blasting application, without bearings, seals, or packings. The interior parts of the pump, including the housings and impellor, are bonded with abrasion-resistant polyurethane rubber to give it a long and maintenance-free life.

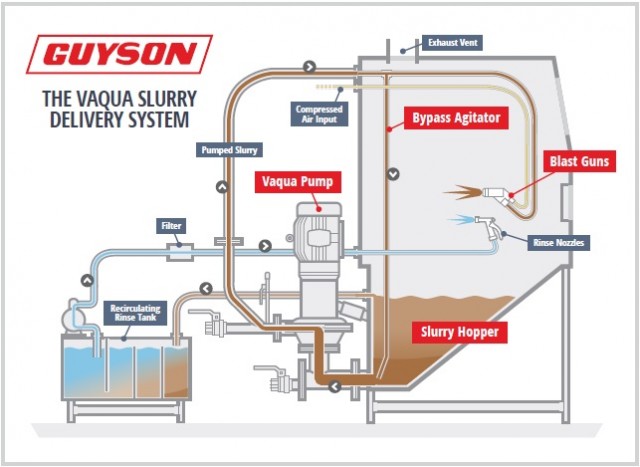

The pump is mounted to the base of our purposefully-designed, steeply-sloped slurry hopper located within the machine enclosure. The angled hopper smoothly and quicly channels the suspended media back to the pump inlet. Our pump and slurry pipework are mounted on the outside of the hopper for ease of maintenance and to maximize the interior space.

In operation, the pump draws the media and water mixture out of the bottom of the hopper and pushes it at a constant pressure and high volume to the Vaqua wet-blast guns. Just prior delivery of the slurry to the blast guns, a portion of the pumped mixture is diverted to a bypass line running down to the bottom of the slurry hopper, where it stirs and agitates the water and media to maintain a consistent mixture.

Within the blast gun, the regulated compressed air is injected to accelerate the slurry and dissipate the controlled amount of water from the flow going to the workpiece. Each blast gun is fitted with a boron carbide nozzle and air jet, and the interior of the gun body is lined with polyurethane for abrasion resistance.

Unlike line-of-sight dry blasting techniques that rely on impact or impingement to do the work, Vaqua wet blasting’s principle is scrubbing the work surface. Carried by the liquid, much of the media contact with the substrate is in a transverse direction. By scrubbing the work surface with the wet blast mixture, contamination, surface deposits, scale or burrs are quickly removed and carried away, leaving a very clean and smooth surface. The removed contamination remains in solution in micron-sized particles and does not become airborne. The wet blast machine is a dustless and self-contained system, and no dust collector is required to operate it.

The Vaqua wet blasting system provides a safe and convenient alternative to other cleaning and surface preparation methods that generate hazardous or objectionable by-products and present costly and unnecesssary handling and disposal problems.

If you have oils or coolant on your product that requires washing and blasting, you certainly will want to consider Vaqua wet blasting, since these operations can be combined into a one step process, reducing the amount of part handling, saving floor space and contributing handsomely to your bottom line.