Unlike competitor suction blast gun assemblies, Guyson’s 400 and 900 air jets and nozzles can be rotated to prolong the life of gun components including the gun body itself. Regular Rotation of the nozzle and air jet also creates a more uniform wear pattern which keeps the blast pattern consistent preventing changes in the part finish.

Simply loosen the lock nut/retaining hardware and give the nozzle and/or air jet a quarter turn (approx. 90°). The more abrasive your media and the more you use your machine, the more frequent your schedule of rotation should be. (Note that threaded boron carbide nozzles cannot be rotated)

Many customers will keep a spare complete gun assembly on hand and switch out the assembly each time so that they can rotate and change out components at their leisure.

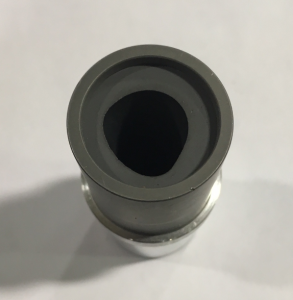

Nozzle:

Wear occurs from the inside out and is especially noticeable when the nozzle has not been rotated on a regulator basis. Hold the nozzle up to the light and look down the bore. Any ripple or “orange peel” effect inside the nozzle will create internal turbulence which reduces abrasive velocity. Replace the nozzle if the bore is worn unevenly and out of round, or when more than 25% over the original ID. (Example: a 1/2” nozzle now has an ID of 5/8” or greater – replace the nozzle.)

Also check the nozzle’s exterior. Rebounding media or interaction with other guns can cause premature failure of the gun or nozzle.

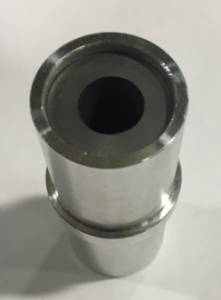

Air Jet:

The air jet wear is from the outside. Worn air jets can cause turbulence and erratic media flow, and gun body wear can be excessive. The gun body should be inspected for wear whenever the air jet is replaced.

For downloadable PDF’s of part information please click here or click below to request a quote