If you own a Guyson Wheelblast machine one of the most important things to know how to conduct is a Blast Pattern Test. A Blast Pattern Test can be beneficial for many reasons these including:

- Ensuring coverage of a part

- Indicating blade, wheel, and armor wear

- Determining shot trajectory

- Anytime a change in Media

With this being said it is important to conduct this when media is being changed, the machine has been moved or received, and service has been done on the machine. Whether you have a 401 or 702 wheelblast machine a blast pattern test is not hard to conduct; the process will be highlighted below:

- Power on the wheel blast machine.

- Locate a piece of sheet metal, cut the sheeting to fit the diameter of the turn table.

- Paint or dye the sheeting, ensuring that the paint is dry before placing it in the machine.

- Place the sheet of metal in the machine.

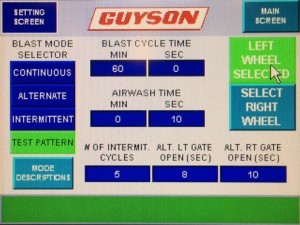

- Locate and press Settings Screen button from the main menu.

- Next select the Test Pattern button and activate the wheel you want to test. For testing one wheel should be selected at a time. Make sure not to do more than three test patterns in a row, this will cause the media to build up on the table and not be reclaimed.

- After the test cycle is run jog the table to unlock the doors and remove the sheeting to see where the media is hitting on the turn table.

- Repeat these steps for the next wheel if necessary. Be sure to line up the sheeting in the same spot for each wheel. If the sheeting is not located in the same spot for each wheel the blast overlap will be hard to see.

- After your test patterns are complete be sure to select the continuous blast option on the setting screen before running the machine again.

For more information on the different types of blasting systems and Guyson media visit https://www.guyson.com

For service on you Wheelblast Machine please submit the form below