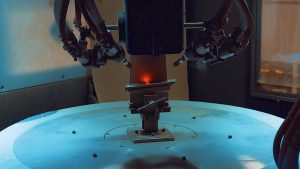

Guysons new multi-axis CNC grit blaster was designed for a prep prior to coat application in the aerospace industry. The heart of this system is based around the blast manipulation with 4 axis controls directed by a Siemens CNC system and roof-mounted 2-axis cartesian gantry with table positional capability of 0-360°. The transfer cart brings the parts to the blast enclosure where 3 axis traverse is mounted with four suction guns that continuously blast’s the part. The cabinet is equipped with a single, vertical servo driven spindle that serves as the 4th axis for the system when paired with the traverse. Maximum media delivery is ensured by a highly efficient gun design and metering system.

With such a complex and precise system safety was a top priority. Multiple strategically placed E-stop buttons are placed around the entire machine. Vertically mounted area scanner and two-sided safety cage to inhibit access to cart and door when in motion. Equipped with Allen-Bradley CR30 software programmable safety relay based safety control.