Shot Peen Standard AMS-2430 for the Automotive and Marine Manufacturing Industry

RSSA-6 Shot Peening System introduces a new level of precision to the work cell and delivers highly consistent quality in the surface treatment results. It can readily be configured to support your process validation requirements.

Guyson engineered and built a shot peening machine for a customer in the Automotive/Marine industry. This small footprint machine is equipped with a spiral separator (media shape separator) to ensure that the S-70 Mil Spec media is correct spec shape to guarantee the intensity that is required to adhere to AMS-2430. In unison with the spiralator a 24″ vibrating screen classifier and 75/12 cyclone reclaimer are used. The cabinet is constructed of 11 gauge continuously welded steel plate and fabricated with rolled edges to eliminate exposed sharp sides or corners. The side door will be double skinned with mitered corners. All doors include electronic safety interlocks to prevent blasting if ajar.

The window(s) are constructed in a frame with replaceable square cut sheet glass on the inside and safety glass on the outside. This allows for quick inexpensive replacement of the inner glass as it becomes abraded.

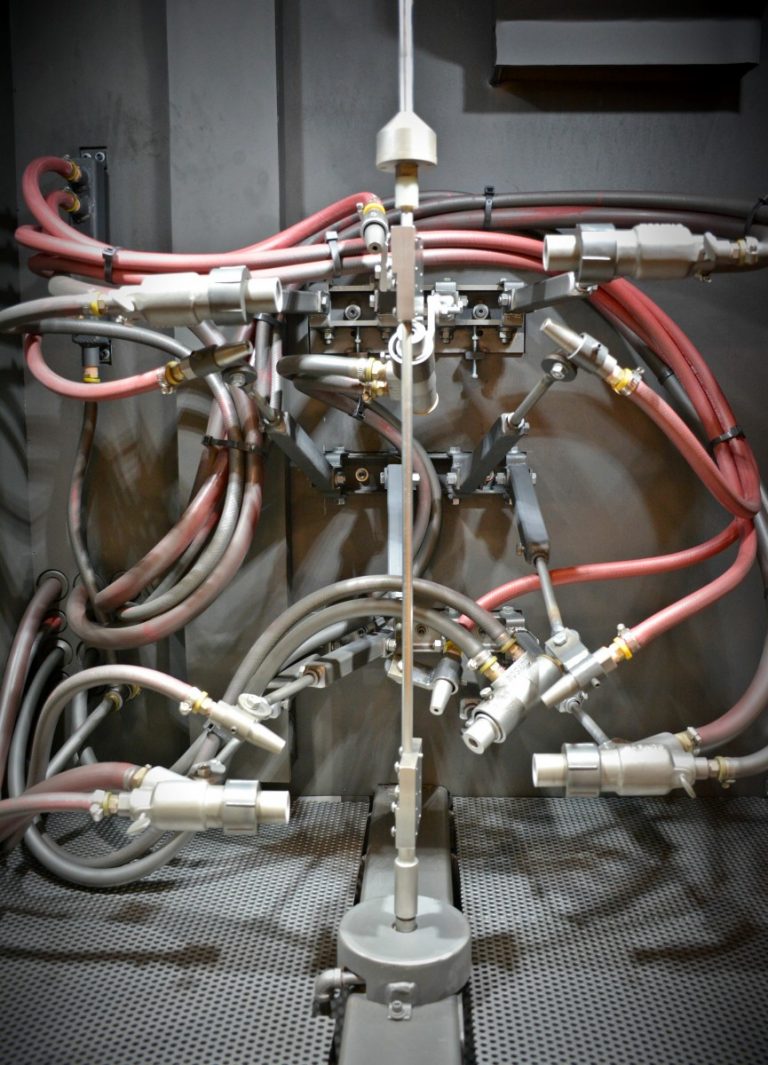

There is a total of 6 suction blast guns with two utilizing individual pressure regulators. The custom fixture designed and built by Guyson, is easily adjusted to re position the 3 guns up or down to accommodate the part height.

All Guyson multi-gun automatics are equipped with a media reclaim anti-clog device. This is a nonadjustable passive unit which prohibits the choking or clogging of the return ducting by either bulk loading or operational cascading media, thus eliminating costly downtime required to clean clogged or blacked airflow passageways.

It also incorporates a spring load feature that allows for seamless loading/unloading as well as maintains complete stability of the part. Having a non automated traverse gives this machine flexibility and affordability.