Precision blast treatment or surface preparation of extra-large components, including aircraft structural parts

Precision blast treatment or surface preparation of extra-large components, including aircraft structural parts

Custom blast and peening systems engineered in-house by the Guyson team, based on client specifications

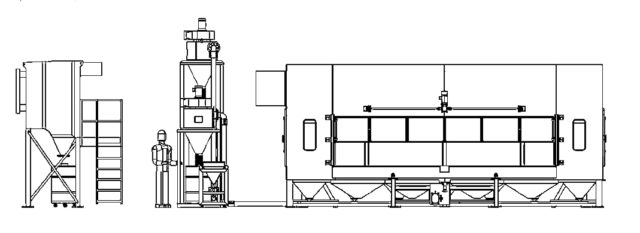

For more than six decades Guyson has built custom blast systems of all sizes to fit our clients specific needs. One of the largest we have ever built is for the Aerospace industry where a large cabinet and specific calibrated treatment was needed to meet AMS2432 specifications.

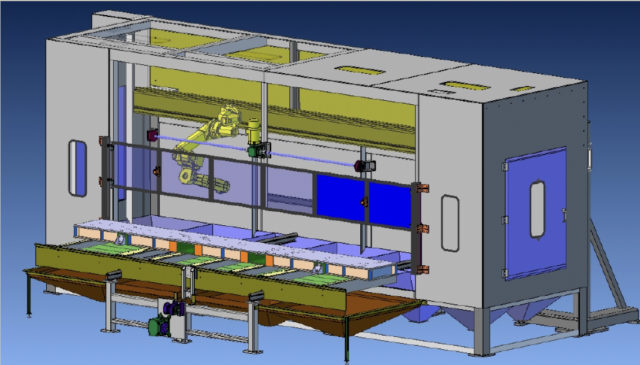

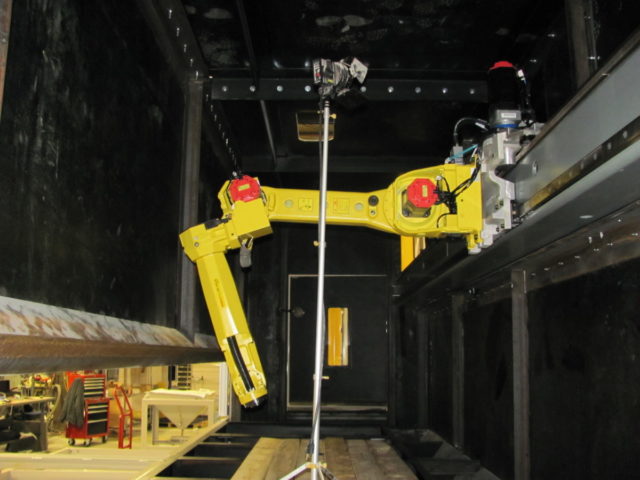

Guyson designed and built a custom-engineered automatic blasting system with a 6-axis robot riding on a rail that runs the length of the blast chamber for a client in the aerospace industry.

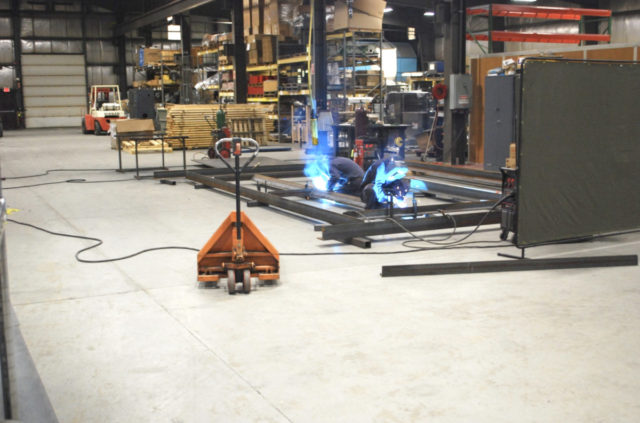

Our In-house manufacturing facility fabricated the blasting system at our location in Saratoga Springs, NY. At this location Guyson has fabricated machines for some of the largest and most technologically advanced manufacturers in the world.

The linear travel of the nozzle manipulator is controlled as a seventh axis of robotic motion. Multiple rails enable two or more robotic arms to be active in the same blast system, when required.

Interchangeable fixtures can be accurately located on the drawer- like transfer cart to allow manual or crane loading. One or more blast nozzles per robot follow the contours of complex-shaped parts, as the correct blast angle, nozzle stand-off distance and surface speed are constantly maintained during the programmed blasting routine. Blast process recipes and motion programs for dozens of different components are stored and recalled by the system’s PLC, and scanning technology can be employed to positively identify the part, the fixture and the correct blast program.

A custom-tailored suit, fabricated with tough, laminated fabric and engineered polymer materials, isolates the robot from the potentially abrasive atmosphere of the blasting enclosure.

The media reclamation and pressure-blast media delivery system, including many available electronic sensing and control options, are engineered according to the requirements of your blasting or shot peening application.

Once the product was assembled and tested to exacting specifications, the machine was broken down into smaller sections and was prepared for shipping to the customers location. We take pride in our ability to prep for transportation.

Installation: the custom robotic blast cabinet was installed at the client manufacturing facility by the Guyson team. It was re-assembled and tested to make sure that it worked as specified by the customer.