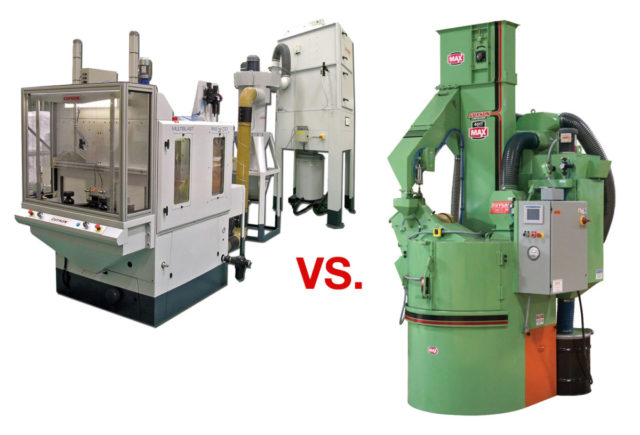

Choosing between an airblast or wheelblast system can be complicated. However, new technologies have now made it harder to choose between these two types of machine as the line between them often gets blurred. Here’s a quick overview on what each machine has to offer.

A Mil Spec Type III prep finish for anodized aluminum parts can be one of the toughest finishes to achieve on a consistent basis and in the past, airblast machines have reigned supreme in this domain. With the capacity to use a wider variety of media at a highly controlled speed, they have an advantage over wheelblast systems. In comparison, only metal-based media can be used in a wheelblast, and with a single speed motor running the blastwheel, it is often tough to get consistent, specified finishes for anodizing and Cerakote

That’s why Guyson Corporation has been working on modifying its wheelblast systems to create a more precise prep-for coat for a variety finishes, including Cerakote, Anodized, Parkerized or even Physical Vapor Deposition coating (PVD coating). With hundreds of hours of blast testing under our belt, we have created finish recipes for each of these coatings. Before, small manufacturing companies had no affordable options when it came to controlling product finishing on a much higher production level other than a manual blast cabinet. And now they do with Guyson’s wheelblast systems.

If you are comparing these two systems, start the process with these two steps:

Step 1: Answer the Following Questions:

- Do you currently have a robust compressed air system at your shop?

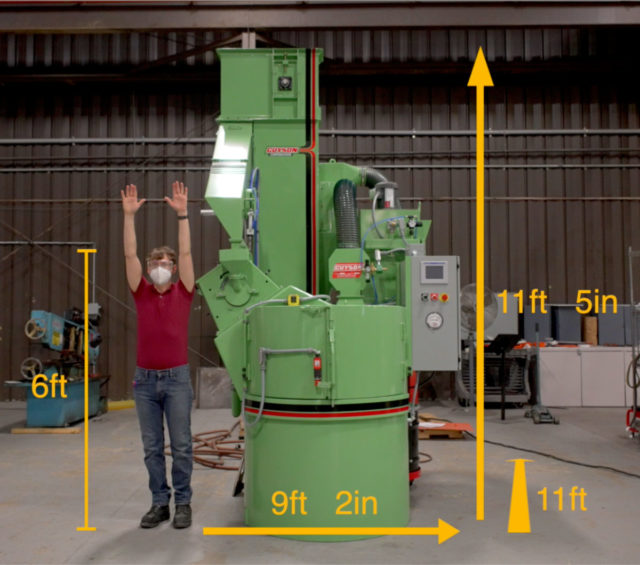

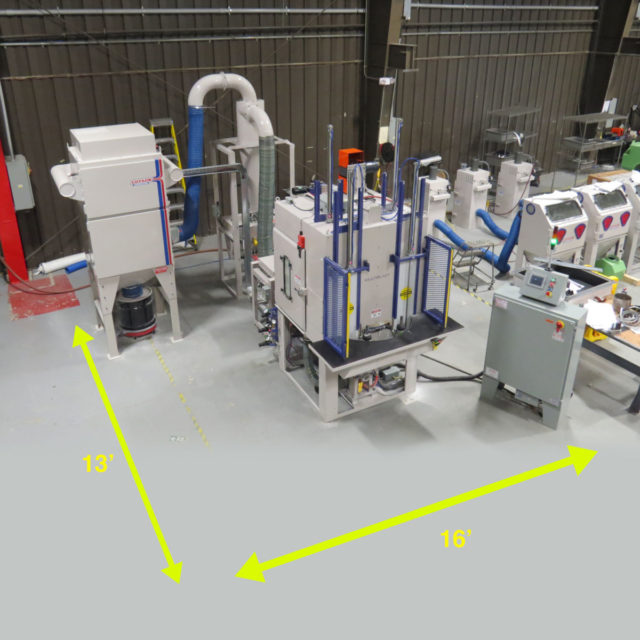

- How much space is available?

- How many parts per hour do you need to blast?

- What type of finish are you prepping for? (Cerakote, Anodize, or Parkerized)

Step 2: Compare These Features

Use the chart below to quickly compare each system:

| Airblast | Wheelblast |

|---|---|

| Flexible use of many medias | Only capable of using metal based media |

| Air Compressor needed (size depends on no. of guns) | Only a small compressor for blow off |

| Reclaim System separate | Reclaim system built in |

| Three phase electric needed | Three phase electric needed |

| Large footprint | Small footprint |

| Multiple sizes available | Two sizes available |

| Fully Customizable for your needs | Minimal customization |

| Exceptionally high production (depends on size and type of machine) | High production |

| low cost per part | very low cost per part |

| high start up costs | low startup costs |

| Automatic and robotic | cabinet can be used to blast many part sizes |

| focus on one product | very flexible to use |

| built and specified to create the perfect finish | flexible for many specific finishes adjustable motor speed & media types |

Airblast indexing machines are capable of reaching up to 600 parts per hour, while a 401T AR-Max can blast up to 400 parts per hour.

Each machine has their own strengths and weakness, but asking the right questions and knowing the benefits of each machine can make this decision easier.

The final decision on whether to choose airblast or wheelblast will be based on your overall budget, the amount of floor space, and whether you want to invest, or currently have, a large air compression system. Guyson has a system that will give you what finish you need, no matter what system you choose.