Guyson built an automated blasting system to replace a time consuming, multi-step process of hand blasted electric housings, rotors, stators and more.

The RXS 800 Indexing Spindle-Blast System was created to be a productive and efficient machine with less downtime and minimal maintenance. The RXS 800 has been established in the automotive industry for decades and comes with many options. The spindle itself is flexible and can be fitted with many types of fixtures to hold multiple parts.

An indexing machine includes multiple chambers allowing a different process to be accomplished as the part rotates from one chamber to another. The applications for this machine include cleaning, descaling, and prep for coating—all in a single pass through the machine.

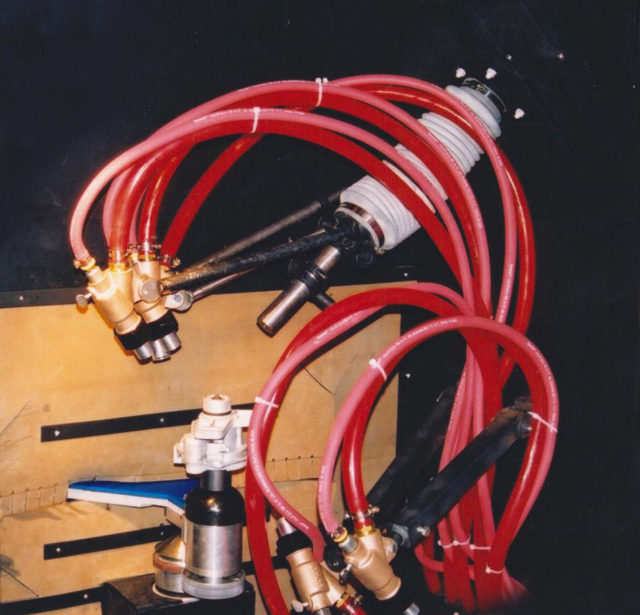

This RXS 800 included (6) Model 900 suction blasting guns propelling glass bead abrasive. This allow several parts to be processed at the same time through multiple steps.

Safety features include a shut down light curtain that stops the machine if a user gets to close while functioning. We also installed an automatic media replenishment system, and a touch screen interface.