If you’ve ever wondered how metal parts can be made stronger and more durable, shot peening is the answer. It’s a process used in industries like aerospace, automotive, and medical manufacturing to extend the life of metal components by making them more resistant to cracks, fatigue, and stress.

How does Shot Peening Work?

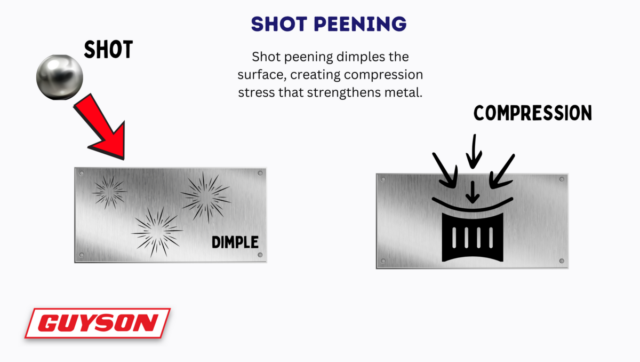

Think of shot peening like a massage for metal. Tiny steel, ceramic, or glass beads (called media) are blasted at the surface of a part using compressed air or a wheel. These small impacts create tiny dimples, compressing the surface and making it tougher. This added strength helps prevent cracks and failures, even under extreme conditions.

Why is Shot Peening Important?

- Increases Durability: Helps prevent metal parts from wearing out too soon.

- Reduces Stress Cracks: Perfect for parts that experience repeated pressure, like aircraft components or automotive springs.

- Improves Performance: Keeps parts stronger without adding extra weight.

Guyson’s Role in Shot Peening

At Guyson, we design and build precision shot peening systems that help manufacturers achieve the perfect balance of strength and durability in their parts. Our machines ensure consistent, repeatable peening results, meeting the highest industry standards for aerospace, automotive, medical, and industrial applications.

We offer a range of customizable shot peening solutions, from manual cabinets to fully automated robotic systems, ensuring precise control over intensity, coverage, and media flow. With decades of expertise, we help manufacturers improve fatigue resistance, prevent stress failures, and enhance the longevity of critical components.

Our advanced shot peening technology is trusted by leading industries worldwide to meet strict specifications like AMS 2430, AMS 2432, and Nadcap compliance, guaranteeing that every component receives the exact treatment it needs.

Want to learn more about how Guyson can help with your shot peening needs? Contact us today!