A marine company engaged Guyson Corporation to build a blasting system that will prep for coat stainless steel tubing surface for a zinc coating.

We found some great old photos going back about 20 years for a custom use machine based on our Model SP 900 machine. (We now call this the Guyson Model 9.) This machines sole purpose was to abrasive blast stainless steel tubing for a preparation for Zinc coating. If you look at the control panel you will see a lot of button rather than the Allen-Bradley touchscreen interface on our current machines.

abrasive blast preparation for zinc coating

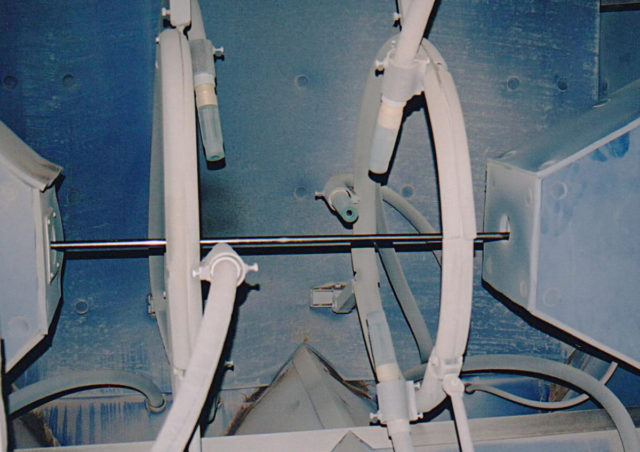

Based on the size of the product and the specifications needed to finish the product, the Model SP 900 had the perfect casing size. It has a large enough cabinet to hold the 6 pressure nozzles which surround the tubing as it enters the blast chamber through the side of the machine.

6 Boride Carbide Nozzles blast the tubing as it passes through the cabin.

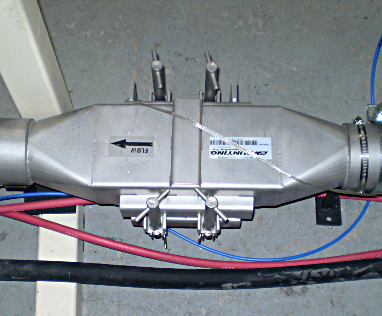

Guyson added a full abrasion protection package which includes rubber cabin lining, urethane ducting, boron carbide nozzles and cyclone lining. These features add to the life to the machine at all points where the blast media creates wear as it passes through the system.

The Guyson engineered pneumatic system keeps a steady flow of media through the 6 gun blasting array.

Other features include magnetic Media separation filter, media level sensor and automatic media replacement.

The Magnetic Media Separation filter removes fines as part of the multi layered reclaim system.