At Guyson, we take the time to engineer the details that make a distinct difference.

Custom features that make a huge difference in blast quality, the life of the machine, and the productivity of your final product. These details include robotic gripper fingers, robot protection suites, and QR code scanning for quality control.

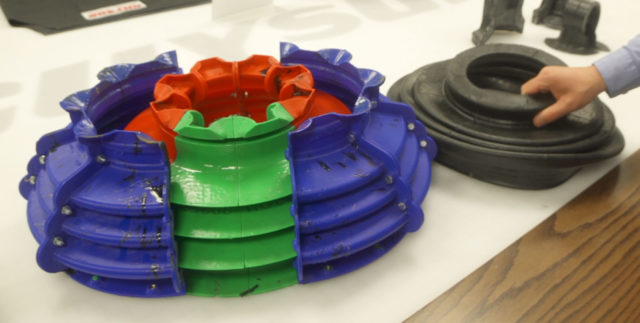

Guyson designs, engineers and makes molds for the protective rubber covers that keep your robot away from blast material.

Guyson custom designs and manufactures resilient gripper fingers, along with blast resistant robot covers. A perfect grip every time makes for a perfect finish. The hardwearing protective hood adds years to the life of your robot.

Robotic gripper fingers that consistently pick and place your product the same way, dust covers that give your robot full and free motion are just a few. Although one detail may not make a huge difference, when you add up all the features, they make your product more productive, last longer and look better.

A perfect robot grip on your product can make the difference between a bad finish and a perfect finish.

When it comes to the your product, consistency is the most important feature your blasting equipment can provide. Your reputation, profitability and productivity are all tied up into one thing, a perfect finish.

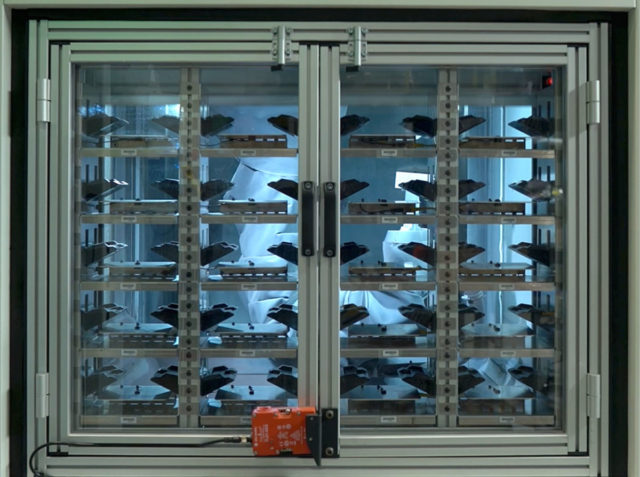

QR coding your products can be a big asset when keeping track of every product. Guyson is one of the few companies in the world that can reach AMS2432 specification for aerospace, where the process of every part is tracked and noted. Guyson has created the most sophisticated systems in the blast industry.

All of our accessories are made at the same facility where the machines are produced. We design them specifically for each client, and then produce and test them in-house. Everything works before it leaves our factory. This is only a small detail that makes our products a real success in the blasting industry.

Guyson Corporation Blast Cabinets are installed in the most advanced manufacturing facilities around the world. They have Guyson Corporation products because they know they can depend on them to last for years, have low maintenance, low cost per product and create a consistent product finish.

At Guyson, we know the details matter.

Call Guyson Corporation for more information on our Wheelblast, dry blast and wet blast machines.