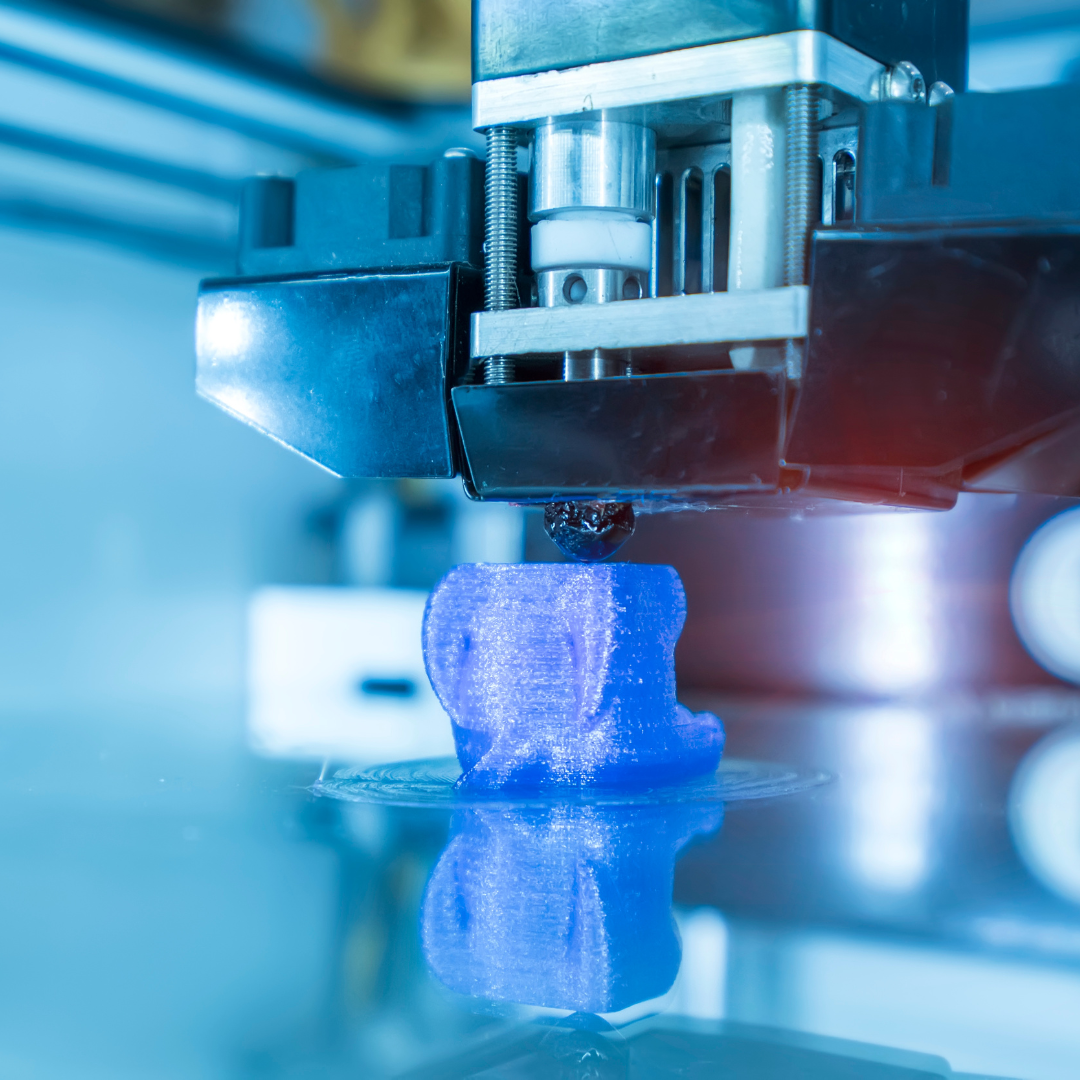

In the rapidly evolving world of additive manufacturing, 3D printing has revolutionized how we approach prototyping, product development, and even end-use production. However, one aspect that often requires attention post-printing is surface finishing. This is where abrasive blast equipment, particularly from industry leader Guyson, becomes indispensable.

Why Surface Finishing Matters

3D printed parts often come with surface irregularities, layer lines, and rough textures that can affect both aesthetics and functionality. Surface finishing processes like abrasive blasting can smooth out these imperfections, resulting in parts that not only look better but also perform better. Improved surface finishes can enhance mechanical properties, improve coating adhesion, and ensure a more professional final product.

Guyson: A Pioneer in Surface Finishing Solutions

Guyson is renowned for its high-quality abrasive blast equipment, offering solutions tailored to a variety of industries, including the field of 3D printing. Our machines are designed to provide consistent, precise, and repeatable surface finishes, which is critical for maintaining the integrity and performance of 3D printed parts.

Key Benefits of Using Guyson Abrasive Blast Equipment

1. Precision and Consistency: Guyson’s equipment ensures uniform surface treatment, which is essential for parts that need to meet strict specifications. Their automated systems can be programmed to deliver consistent results, reducing the risk of human error.

2. Versatility: Whether you are dealing with plastic, metal, or composite 3D printed parts, Guyson offers a range of abrasive media and equipment options to handle various materials and finishes.

3. Efficiency: Guyson’s machines are designed for high throughput, making them suitable for both small-scale operations and large-scale production environments. Their efficient media recycling systems also minimize waste and reduce operating costs.

4. Customization: Understanding that different projects have unique requirements, Guyson provides customizable solutions. Their engineering team works with clients to develop equipment configurations that meet specific needs.

Application Examples

1. Prototype Development: For prototypes that need to closely mimic final production parts, achieving a smooth, professional finish is crucial. Guyson’s abrasive blasting systems can remove layer lines and prepare prototypes for painting or further testing.

2. End-Use Parts: When 3D printed parts are used in their final form, surface quality can impact performance. For instance, in aerospace or medical applications, even minor surface flaws can lead to significant issues. Guyson’s equipment ensures these parts meet stringent quality standards.

3. Tooling and Molds: 3D printing is often used to create tooling and molds. Abrasive blasting can refine these tools, ensuring they produce high-quality end products.

How to Implement Guyson Abrasive Blasting in Your Workflow

1. Evaluate Your Needs: Assess the types of materials you are working with and the surface finish requirements for your parts. This will help determine the appropriate abrasive media and equipment.

1. Evaluate Your Needs: Assess the types of materials you are working with and the surface finish requirements for your parts. This will help determine the appropriate abrasive media and equipment.

2. Consult with Guyson: Engage with Guyson’s experts to discuss your specific applications. They can provide insights into the best equipment and media choices, as well as offer customization options.

3. Set Up and Training: Once you have chosen the right equipment, ensure proper installation and training for your team. Guyson offers comprehensive support to help you integrate their systems into your workflow seamlessly.

4. Optimize and Maintain: Regular maintenance and optimization of your abrasive blasting process will ensure consistent results and prolong the lifespan of your equipment. Guyson provides ongoing support and maintenance services to help you stay efficient.

Integrating Guyson abrasive blast equipment into your 3D printing workflow can significantly enhance the quality and performance of your printed parts. With their precision, versatility, and efficiency, Guyson’s solutions are a valuable investment for any additive manufacturing operation looking to achieve superior surface finishes.

Whether you’re producing prototypes, end-use parts, or tooling, Guyson’s abrasive blasting technology can help you take your 3D printed parts to the next level. Invest in quality surface finishing and experience the difference in your products’ performance and appearance.