Every so often a project comes around that requires an “out of the box “solution from our engineering team .This robotically loaded system was just recently completed for a large healthcare provider that produces Neuro Perforator tools . The Fanuc M10 loading robot station is controlled by Guyson ‘s proprietary  loading software .Safety to the robot area is provided through a Fortress keyed system .The customer required strict cleanliness and sound level compliance and a “Tamer” full enclosure was selected as the solution .

loading software .Safety to the robot area is provided through a Fortress keyed system .The customer required strict cleanliness and sound level compliance and a “Tamer” full enclosure was selected as the solution .

3-D printed grippers were designed to be easily changed for various part diameters . Tray recognition, part /no-part verification , and sampling and drop-off were standard features required by the customer .

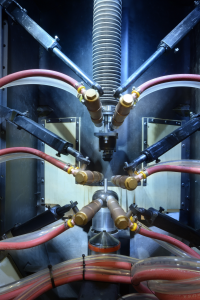

The grit blasting cell was made up of (2) highly automated RXS-400 machines . Each equipped with ethernet Festo pneumatic values , in-line magnetic separators, Guyson precision spindle positioning module, Keyence light curtains and laser part verification .

I know everyone here at Guyson is very proud to see this system operating and knowing it will be producing the highest quality tools that someday will save people lives .

Let Guyson build a system of your dreams .We have the knowledge to do it .