Guyson’s Vaqua Wet Blasting is a unique finishing process. It is the only finishing process that can degrease, deburr, surface condition and leave a surgically clean surface in one operation.

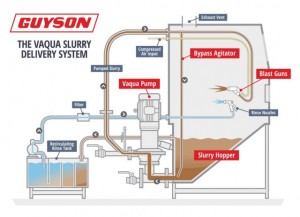

Our patented Vaqua slurry pump is the heart of the process. The pump is designed without bearings, seals, or packings in contact with the slurry. All areas in the pump where slurry flows are wear resistant hot pour polyurethane. The pump is mounted external to the cabinet for ease of maintenance; no components of the Vaqua slurry delivery system are located below the water inside the cabinet. Power for the Vaqua slurry pump comes from electric motors ranging from .5 to 40 horsepower depending on the application.

The Vaqua process blast guns are designed for easy handling and mounting. All gun designs are fitted with Boron Carbide nozzles and various air jets. Guns can be broken down into individual components so only worn components can be replaced.

- Deburring

Why go wet blast?

- Simultaneous degreasing, deburring and surface conditioning

- Can accommodate wet components

- Media surface impregnation is eliminated

- Eliminates the explosion hazard created when processing Titanium

- Allows the use of inhibitors to prevent corrosion, during and after processing

- Reduces component erosion and damage to sharp edges and details

- Provides a more economic use of blast media

- Can prove faster than dry blasting due to greater media flow

- Produces a cleaner, brighter finish by scrubbing and washing away contaminates

- Offers a wide range of process control without changing the media

- Elimination of dust, reducing environmental pollution.

Contact us today to learn more how Wet blasting can help your process !