In surface preparation, selecting the right blasting process is essential to achieving the desired finish and maintaining component integrity. Guyson’s Vaqua wet blast technology leads the industry in effective, efficient wet blasting that minimizes dust and manages delicate surfaces, making it ideal for a broad range of applications. Here, we’ll explore how the Vaqua wet blast process stands out and why it’s an invaluable asset in various industrial settings.

The Science Behind Wet Blasting

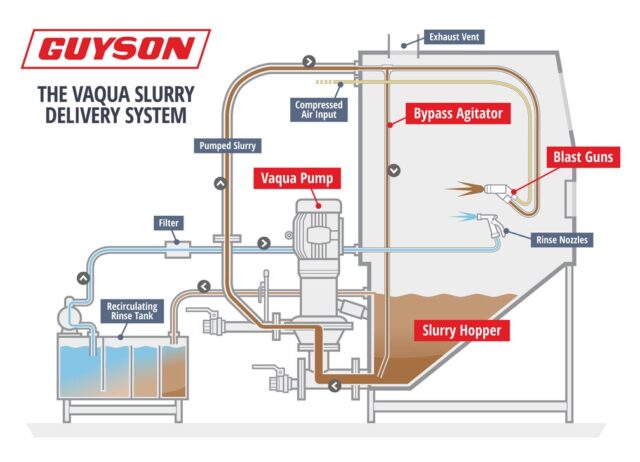

Wet blasting combines abrasive media with a controlled water flow to deliver a precise, dust-free blasting experience. Unlike dry blasting, where friction and high velocities can generate excess heat and fine dust, wet blasting involves a water-based slurry that encapsulates particles, reducing dust and ensuring that abrasives don’t embed into the workpiece surface.

For industries working with delicate surfaces or needing a polished finish without contamination, this process is game-changing. The result? Cleaner, more consistent surfaces achieved with reduced risk of surface damage and contamination.

Vaqua Wet Blast Process: Built for Precision and Versatility

Guyson’s Vaqua wet blast process is designed to handle a range of surface challenges, from complex geometries to sensitive materials. The system combines water, air, and abrasive media, offering precision that dry blasting often cannot. Here’s how the Vaqua stands out:

- Adaptable to Different Materials: From metals to composites, Vaqua’s adjustable parameters allow operators to tailor the process to specific substrates, optimizing outcomes without compromising surface integrity.

- Reduced Surface Stress: Because wet blasting minimizes surface stress, it’s ideal for components that cannot withstand high-temperature or high-stress environments.

- Consistent Quality: The constant slurry flow produces a uniform surface, essential for industries where surface consistency is non-negotiable, such as aerospace or medical manufacturing.

Key Benefits of the Vaqua Wet Blast System

- Dust-Free Operation: The water-based approach nearly eliminates dust production, creating a safer work environment while simplifying cleanup and preventing media recontamination.

- Enhanced Precision: Wet blasting allows for greater control over abrasive impact, meaning more delicate or polished surfaces can be achieved without sacrificing accuracy.

- Sustainability: Wet blasting can reduce environmental impact, with media containment and controlled water flow that minimizes waste and reduces cleanup requirements.

Applications Across Industries

Guyson’s Vaqua wet blast process serves industries with unique needs for surface preparation, coating, and component cleaning. Examples include:

- Aerospace: Cleaning turbine blades or engine parts where precision and stress reduction are crucial.

- Medical Devices: Preparing stainless steel or titanium components for coatings that require a pristine, non-contaminated surface.

- Automotive: De-painting or prepping surfaces on sensitive parts, ensuring minimal material degradation.

Elevate Your Surface Preparation with Guyson’s Vaqua Technology

With the Vaqua wet blast process, you achieve results that are both high-quality and environmentally sound. Whether your industry requires gentle cleaning, consistent finishes, or contamination control, the Vaqua process has proven to be an asset to businesses globally.

Guyson’s commitment to precision, efficiency, and safety makes their Vaqua wet blast systems a go-to choice for industries that can’t compromise on surface quality.