When is it more cost effective to stop making repairs and start looking at purchasing a new system? Here are a few of the major areas that customers should be looking at:

- If the bottom lip of the cabinet where the door seals is no longer making a complete seal and the doors can no longer shut.

- If the doors do not shut properly customers can potentially have a fall hazard on their hands from media leaking out of the system, this will have a direct effect on media costs. Customers will start spending more money on media.

- When the integrity of the internal brackets designed to hold the hanging wall armor are no longer functional.

- Improper upkeep of the blastwheel blades and blastwheel armor, this will have a direct effect on your blastwheel itself. Additionally, replacing the blades will maintain the correct balance of the wheel and ensure consistent media coverage.

- If the internal neoprene/retaining straps of the cabinet are wearing. This neoprene is designed to deflect the abrasive from hitting the cabinet walls. Once this lining starts wearing in certain areas it will need to be replaced. Not replacing it when wear points are noticed will allow media particles to seep into the cracks and ultimately the media will start to eat away at the cabinet walls.

Reason you may see increased wear on your cabinet:

- Not using the correct media. Having an overly aggressive media (shot, grit) can cause increased wear on internal components of the blast chamber. Media designed specifically for these systems, Guyson Metalbead is 46 Rockwell versus more destructive media(s) that can be up to 52 Rockwell hardness.

- Improper system maintenance, every customer’s application and cycle times are different but as a general rule of thumb the following items should be checked:

| 1. Blastwheel Blades

2. Regulator 3. Distributor 4. Blastwheel Armor |

1. Elevator

2. Blast Cabinet Armor 3. Hose 4. Blastwheel |

1. Entry Side Armor & Support |

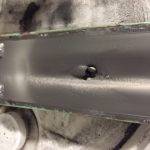

- Damaged Wheelblast

- Damaged Wheelblast

- Damaged Wheelblast

If you have any questions about replacing your parts ,please contact customer service.