Your Guyson wheel blast machine has advanced abrasion protection in the form of thick armor plates that line the blast chamber in all areas directly exposed to the blast stream.

The protective armor is case from extremely hard and wear resistant alloy to extend service life. However, due to constant contact with high volumes of blast media very gradual wear does occur. If this armor is not replacing in time, the walls of the blast cabinet as well as other working parts will be exposed to direct blast. This could QUICKLY result in permanent damage to parts of the machine

How to inspect your Wheelblast Armor?

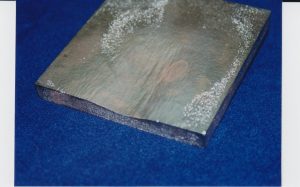

- Remove each piece of armor for close inspection. Check the thickness at various points of the plate. Any places armor is less than 1/8’ thick or 25% less then original thickness

Worn Armor

- If wear is discovered on armor ,inspection all other areas that may have been exposed to direct blast

- Extremely irregular wear of the armor can help you detect a need to adjust the blast pattern.(Please see you Operators Manual or if you do not have one please request one on your MyGuyson Account )

- Always refer to drawings in the Operators Manual for your own machine to identify part numbers

Wheelblast Replacement Parts

Direct Drive

Belt Driven

If you have any questions about replacing your armor ,please contact customer service.