GUYSON VAQUA WET BLAST SYSTEMS

1. Increases rubber bonding up to 120%

2. Scrubs parts clean while blasting.

3. Uses 70% less media than dry-blasting.

4. Corrosive resistance inhibitors increase product durability.

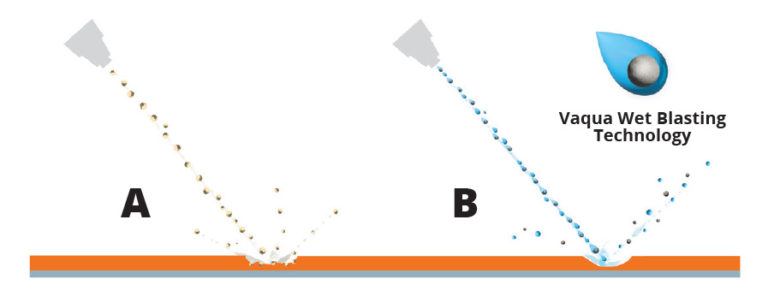

Why Guyson Vaqua is Best for Rubber Bonding

A. Crude dry grit or sand blasting direct media to metal contact. Continuation of downward force causing impregnation.

B. Vaqua wet blast processing water buffer between metal and media cushions shock and deadens downward force. This is the best process for rubber bonding.

FEATURES:

VAQUA PUMP

• Specifically designed for wet blast systems

• Externally mounted

• High flow capacity

• Does not contain seals, bearing, or packing

• Lined with hot poured polyurethane

MINI CYCLONE MEDIA FILTRATION

• Specifically designed by Guyson to classify media within slurry line

BLAST GUN

• All parts either made from or line with polyurethane

• Individual parts can be replaced rather than whole gun

• More control – effective blast pattern of 2 inches

MEDIA SEPARATOR

• Takes media out of slurry within minutes

See Our Full Line of Wet Blast Systems at www.guyson.com

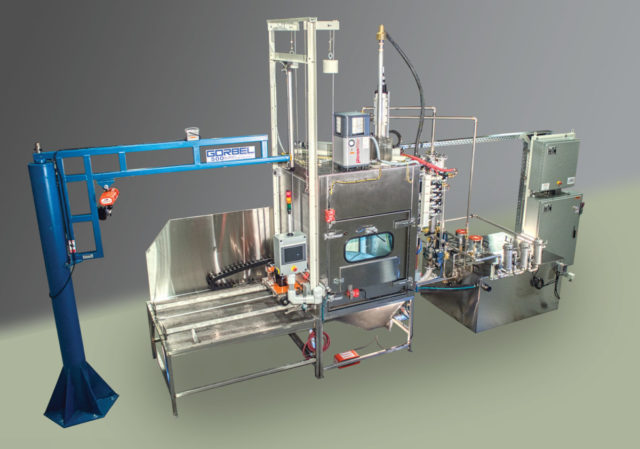

Guyson Custom Engineer Wetblast Systems

Auto Komet Automated Industrial Blast System

Affordable Manual Wetblast System with Large Cabinet

Affordable Manual Wetblast System for shop usage