When a major fortune 500 Aerospace company , who had built their reputation on being “dependable “ , selected Guyson to  design and build a custom grit blaster for batch processing gas turbine blades; our engineering team realized that this was something truly unique . Our customer was involved throughout the design of the system and was impressed with how we were able to completely blast the blades in one operation.

design and build a custom grit blaster for batch processing gas turbine blades; our engineering team realized that this was something truly unique . Our customer was involved throughout the design of the system and was impressed with how we were able to completely blast the blades in one operation.

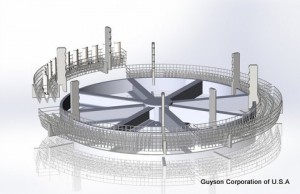

Guyson developed a “SP-10” semi-automatic Grit blast system using its precision 150/16 reclaim system with vibrator and heater installed on the media hopper to keep the fine 240 grit alumina oxide flowing . The six Guyson guns are mounted to the gun oscillator that moves at a programmed RPM, adjustable on the HMI. The table speed is also adjustable through the HMI and can easily handle the large 34” diameter basket and its 100 lb load.

Guyson’s new vertical door design provides the protection required to comply with the maximum 80 DBA noise level requirement while also making the loading and unloading of the basket segments a breeze.

The secret to being able to completely blast the blades is the segmented polyurethane coated basket. This basket was custom engineering to prevent part on part impingement and masking .

Don’t compromise for a “off the shelf” system. Contact the experts at Guyson and find out how we can build you a custom system in just under 16 weeks or less!