Identification of components by part number and name and matching them with the correct program is greatly simplified using scanning technology, but we can help the operator confirm the match by displaying the load location of the part and a visual representation of the component with key dimensional data. It is common for the shot peening system to recognize a hundred or more different parts, each with a distinct process program.

Identification of components by part number and name and matching them with the correct program is greatly simplified using scanning technology, but we can help the operator confirm the match by displaying the load location of the part and a visual representation of the component with key dimensional data. It is common for the shot peening system to recognize a hundred or more different parts, each with a distinct process program.

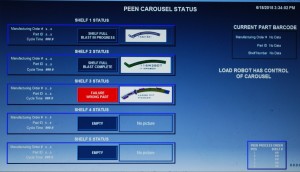

While the system status, processing data and cycle progress for a component being peened is being displayed at the HMI, one or more components can be queued in advance of processing, based on their loading location.