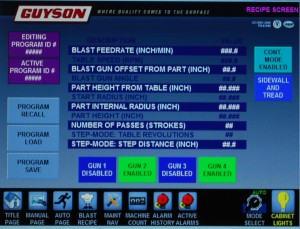

The PAC and robot controller are capable of storing and recalling all process parameters for a virtually unlimited number of different components. The program for each part includes nozzle or component motion control, as well as closed-loop control settings and limit set points of all vital parameters, including shot flow rate and blast pressure for each peening nozzle, shot size in multiple-media shot peening systems and the nozzle selection in tool-changing robotic peening systems. All program data are shared with the monitoring and logging PC.

The PAC and robot controller are capable of storing and recalling all process parameters for a virtually unlimited number of different components. The program for each part includes nozzle or component motion control, as well as closed-loop control settings and limit set points of all vital parameters, including shot flow rate and blast pressure for each peening nozzle, shot size in multiple-media shot peening systems and the nozzle selection in tool-changing robotic peening systems. All program data are shared with the monitoring and logging PC.

Modification of process programs or entry of new program data is password-protected and restricted to authorized users.