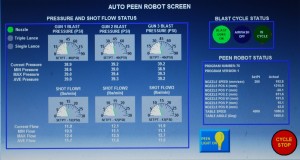

Throughout the peening process cycle, each second, data on critical process parameters and overall system status is refreshed and displayed on our intuitive graphical HMI and recorded by the monitoring PC. Should an out-of-limit condition or other malfunction occur, the operator is alerted by an alarm, the event is logged and time stamped, and the system displays the location of the problem with simple instructions for corrective action. When conditions are back to normal, step-by-step prompts are provided to resume operation of the shot peening system.

Throughout the peening process cycle, each second, data on critical process parameters and overall system status is refreshed and displayed on our intuitive graphical HMI and recorded by the monitoring PC. Should an out-of-limit condition or other malfunction occur, the operator is alerted by an alarm, the event is logged and time stamped, and the system displays the location of the problem with simple instructions for corrective action. When conditions are back to normal, step-by-step prompts are provided to resume operation of the shot peening system.

U.S. & Canada 1-800-228-7894

Customer Service Hotline 1-800-633-6677

International 518-587-7894

E-mail info@guyson.com

Contact PageFor directions & quote request