The Role of Robotics in Modern Manufacturing for Surface Finishing

In today’s fast-paced manufacturing world, robotics plays a crucial role in boosting efficiency, precision, and innovation. One key area where robots have made a significant impact is surface finishing. Let’s explore how robotics is transforming this process, improving quality, cutting costs, and ensuring consistent results. Precision and Consistency Robots offer unmatched precision and consistency in […]

Contact Us Zoho Test

Phone – 1-800-633-6677 Parts & Media – Press 1 Call Guyson for OEM Spare Parts and blast Media (If you want to be contacted about Parts and Media specials, login or register at my.guyson.com) Machine Sales – Press 2 Need a machine quote or have a question about a Guyson product? Talk to a knowledgeable Guyson […]

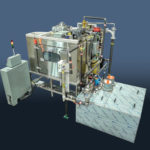

Introducing “THE NEW 201T AR Mini” Wheel Blast Machine

The Guyson AR Mini is an affordable blast finishing machine that is the perfect prep for anodizing, Cerakote or a cosmetic finish. The 201T AR Mini is the ideal machine for small to medium firearms manufacturers, coating shops, or any company in need of a smaller footprint high production machine. Are you having trouble increasing […]

Is Wet Blasting Safer Than Dry Blasting?

Wet blasting involves using water and an abrasive media to clean or prepare a surface, whereas dry blasting uses only an abrasive media.

Blast Cabinet and Vortex Dust Collector

The Camfil Vortex wet dust collector is an advanced and efficient filtration system designed to remove airborne particles from industrial, commercial, and residential indoor environments. This cutting-edge filtration system uses a combination of cyclonic separation and wet scrubbing to trap and collect dust particles before they can be released into the air.

Wet Blast vs Chemical Etching for Bonding Rubber to Metal

The downside is that the chemical etching process takes longer than industrial wet blasting.

How Glass Mold Cleaning Paved the Way for Automotive Part Reconditioning.

“They learned of the 401T Wheel Blast System, successfully developed by Guyson for the glass bottle container industry where the cleaning and maintenance of finely machined molds had alway been a problem. Cleaning had to be fast, thorough and economical without disturbing the metal and affecting the dimensional tolerances. In other words, the problem was the same as those faced by engine re-manufacturers.