Guysons Model RXS-400 (Rotary Indexing Spindle) system is designed to accommodate specific shot peening specs. The system is equipped with a Model 75-12 Cyclone Reclaimer Classifier for size control,Spiral Separator for shot shape control and D-2000 Dust Collector. At Guyson we strive to be new, innovative and the leader in the precision industry. We accomplish this by thinking outside the box.

Shot peening requires precision Almen test strip fixtures to ensure accuracy on the final part. Many parts such as gears, turbine blades, and engine casings require test strips to be located at obscure angles to provide accurate results. A higher level of accuracy can be achieved for Almen test strip placement by using a 3D printed alignment structure during the fabrication process. This accuracy is required for compliance to such specifications as AMS- 2430,AMS-2432,Mil-S-13165 and BAC-5730.

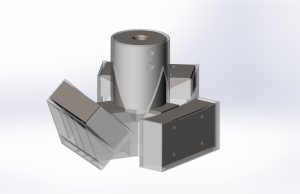

Almen test strip mounting plates are strategically placed within a 3D CAD model to locate the areas of the part requiring specific peening intensities. Once the locations are set, a structure is designed to hold each test strip mounting plate during the welding process. The structure is then 3D printed in thermoplastic using a FDM process. The 3D printed structure is sent to the weld shop to be used as a fabrication jig. The welder can quickly and accurately place and tack weld each test strip mounting plate without deforming the thermoplastic. Once all positions are set, stronger welds are added and the thermoplastic structure melts and is removed. The finished fixture can now be used to precisely mount Almen test strips for accurate testing of saturation, peening intensity, and gun alignment.

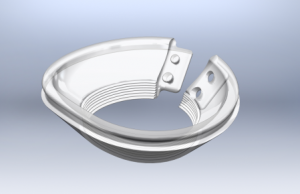

Many parts require precise masking and protection for certain zones directly adjacent to areas requiring blasting. Durable molded blast resistant materials are utilized to accurately define these zones. The areas and surfaces needing protection are identified within a 3D CAD model of the part. Masking is designed with several parameters in mind: blast media, pressure, and angle. Molds can be made of fiberglass, silicone, or urethane depending on size, shape, and final mask material.

Different materials will deteriorate at various rates depending on the blast angle. For example, a molded urethane will survive longer in direct blast than it will at sharp angles. Among other considerations, the designer must take into account how often the operator will remove the mask, and the ease of mask removal.